-

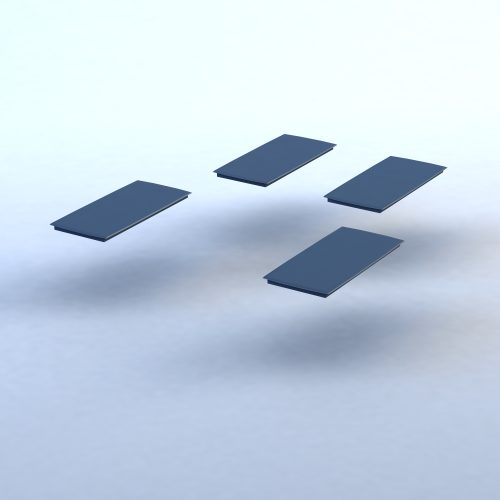

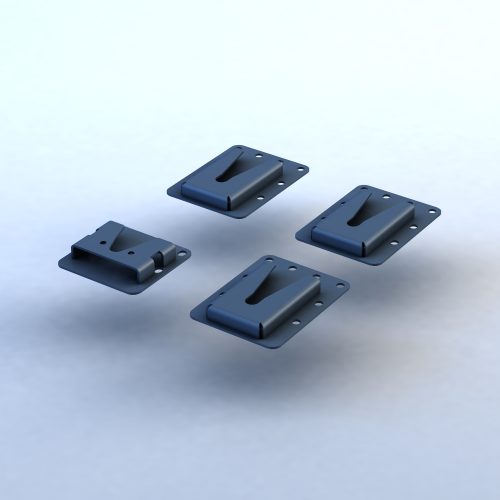

The Support plates ensure that the wooden plate is not dented by the wheels of the Carrier when it is loaded onto the veicle interface. For installation we advise you to watch the assembly film of the vehicle interface before starting assembly.

Application:

Vehicle interface of all models -

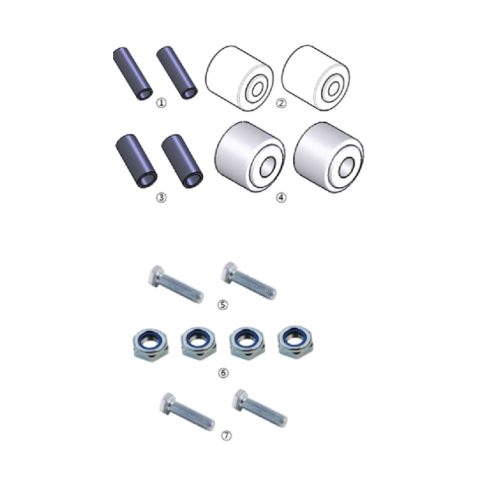

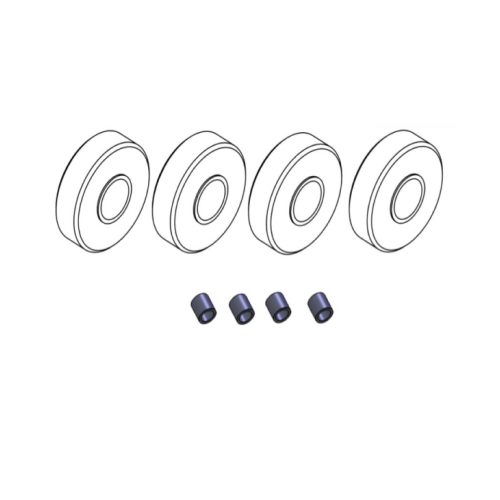

The wheels support frames ensure that the carrier rolls on the car interface. It is very important that the bolts are properly greased during installation. This is to prevent frictional noise.

Applications:

All models -

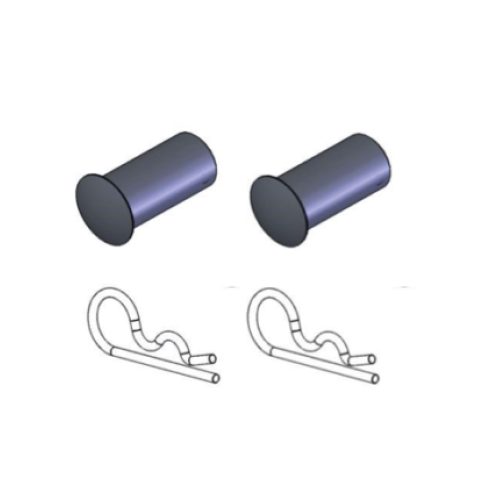

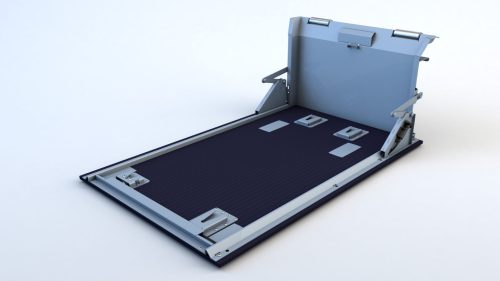

The “Shaft with spring cotter” forms the pivot points of the Loadingtray. These must be greased during assembly. For installation we advise you to watch the assembly film of the vehicle interface before starting assembly.

Application:

Vehicle interface of all models -

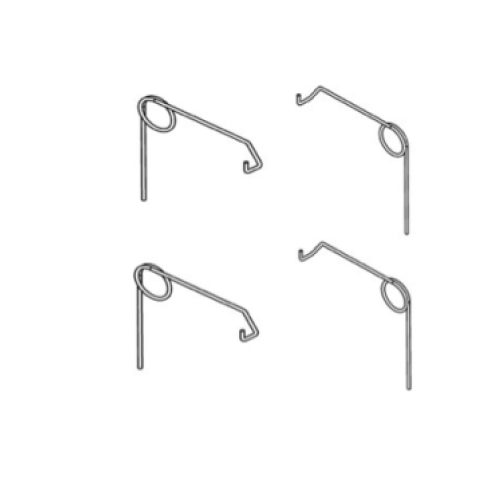

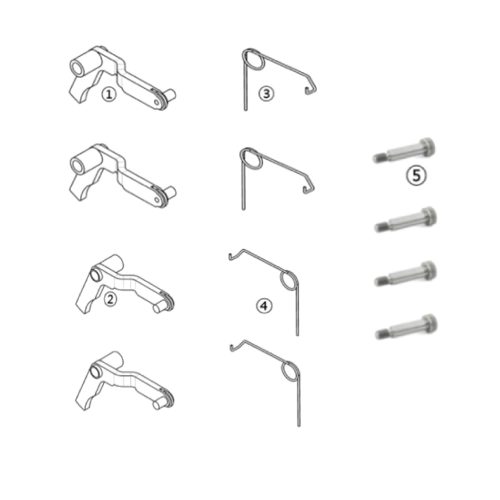

The safety locks are the part of the mechanism that lock and unlock the legs. Assembly requires some Dynnox expertise. The bolts should be mounted with loctite to prevent loosening of the screws. Note: when replacing these parts the clearance of the legs must be reset. See manual. Also watch our assembly video.

Applications

All models -

These casters are usually used for flat surfaces for both indoors and outdoors. They can handle 70 kg per wheel. The use of these casters makes starting a carrier smoother.

-

The Brackets are made of stainless steel and ensure the positioning and anchoring of the frame on the laoding tray. For installation we advise you to watch the assembly film of the vehicle interface before starting assembly.

Application

Vehicle interface of all models -

These nylon wheels are mounted on the bottom of all types of chassis. When mounting these wheels we advise the use of grease to avoid frictional noise. The durability of these wheels depends on the beauty of your vehicle interface when loading and/or unloading a chassis.

Applications

All models