-

Der komplette XL53 besteht aus dem Fahrgestell L46 + der Autoschnittstelle + der Holzplatte L46. Damit haben Sie alles, was Sie für den Dynnox XL53 benötigen. Das mobile Dynnox Transportsystem ist in drei Dimensionen erhältlich und kann in allen Arten von Firmenfahrzeugen eingesetzt werden. Der XL53 ist unser größtes Modell. Der Dynnox XL53 bildet die Basis für jedes schmale mobile Transportsystem in Firmenfahrzeugen. Das Fahrgestell wiegt nur 80 kg und hat eine Tragfähigkeit von nicht weniger als 250 kg! Sie können eine unserer bewährten Anwendungen wählen oder ein Installationsmodul entwerfen, das perfekt zu Ihrer Situation passt; das intelligente System hält alles leicht und einfach beweglich.

-

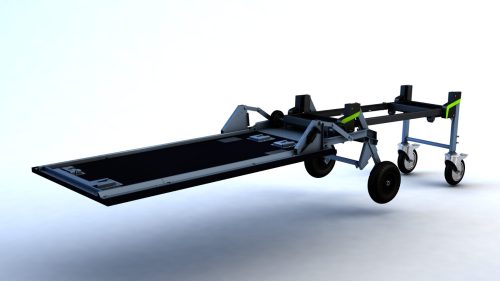

The complete XL53 is composed of the chassis L46 + the car interface + the wooden plate L46. With this you have everything you need for the Dynnox XL53. The mobile Dynnox transport system is available in three dimensions and can be used in all types of company vans. The XL53 is our largest model. The Dynnox XL53 forms the basis for every narrow mobile transport system in company vehicles. The undercarriage weighs only 80 kg and has a bearing capacity of no less than 250 kg! You can select one of our proven applications or design an installation module that perfectly matches your situation; the smart system keeps everything light and easily moveable. For this model a detachable auto interface is available. This allows flexible deployability of the Dynnox. This way you can use the Dynnox for project-based work, easily smooth out the load floor or take out the Dynnox in case of an exchange of company vehicles. Read more about the XL53 or contact us!

-

The complete XL36 is composed of the chassis L46 + the car interface + the wooden plate L46. With this you have everything you need for the Dynnox XL36. The mobile Dynnox transport system is available in three dimensions and can be used in all types of company vans. The XL36 is our narrowest model. The Dynnox XL36 forms the basis for every narrow mobile transport system in company vehicles. The undercarriage weighs only 80 kg and has a bearing capacity of no less than 250 kg! You can select one of our proven applications or design an installation module that perfectly matches your situation; the smart system keeps everything light and easily moveable. For this model a detachable auto interface is available. This allows flexible deployability of the Dynnox. This way you can use the Dynnox for project-based work, easily smooth out the load floor or take out the Dynnox in case of an exchange of company vehicles. Read more about the XL36 or contact us!

Dimensions

The Dynnox XL36 has a frame width of 360 mm. The detachable auto interface is structured around a wooden plate of at least 12 mm thickness. From 16 cm above the frame the installation module could be up to 20 cm wider. -

Die Fahrzeugschnittstelle besteht aus drei Kernteilen: der Ladeplattform, der Ladeschale und der Holzplatte. Der Carrier XL36 ist nicht im Lieferumfang enthalten. Die Fahrzeugschnittstelle hat drei wesentliche Funktionen: A) durch die Ladeschale wird der Mechanismus entriegelt. Siehe Art. Ladeschale B) es führt das Fahrgestell im Fahrzeug. C) Es verriegelt das Fahrgestell im Fahrzeug.

-

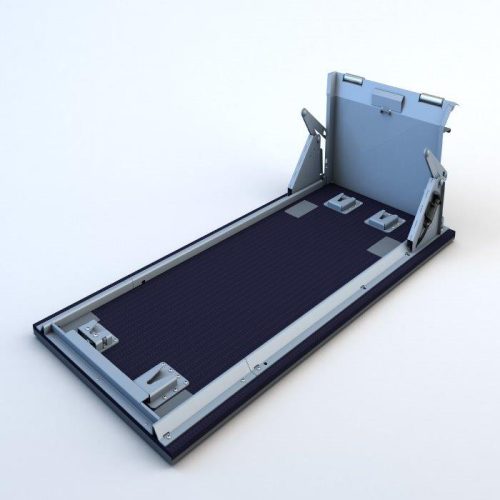

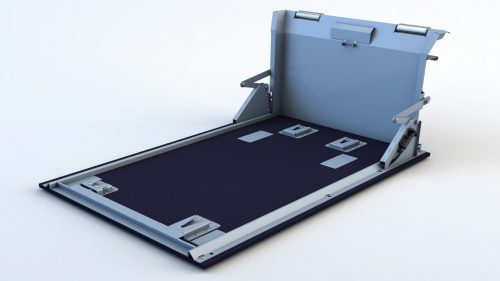

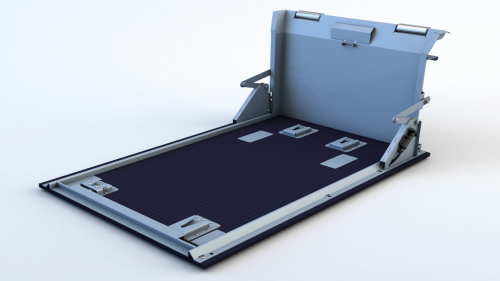

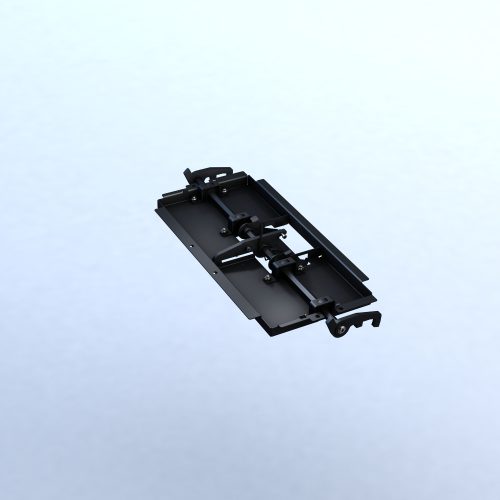

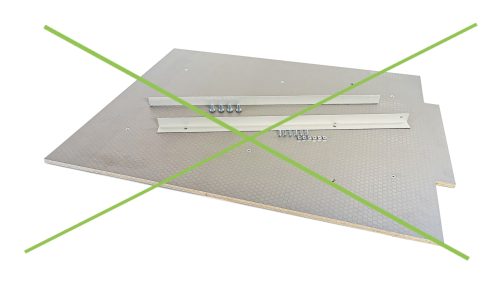

The vehicle interface is made of three core parts: the loading platform, the loading tray and the wooden plate. The Carrier L46 is not included. The vehicle interface has three essential functions: A) due to the loading tray it unlocks the mechanism. See art. loading tray B) it guides the chassis in the vehicle. C) it locks the chassis in the vehicle.

-

The vehicle interface is made of three core parts: the loading platform, the loading tray and the wooden plate. The Carrier XL36 is not included. The vehicle interface has three essential functions: A) due to the loading tray it unlocks the mechanism . See art. loading tray B) it guides the chassis in the vehicle. C) it locks the chassis in the vehicle.

-

The XL36 chassis is the longest and the thinnest Dynnox. The front and back are the same width. The car interface is not included. Due to its length and width, it is often used when enough space in the car is also important. An application of approx. 50 cm wide, 140 long and 120 high can be mounted on the frame, provided that the mass (load) is well distributed in the application. Read more about the XL36 or contact us!

-

The XL36 chassis is the longest and the thinnest Dynnox. The front and back are the same width. The car interface is not included. Due to its length and width, it is often used when enough space in the car is also important. An application of approx. 50 cm wide, 140 long and 120 high can be mounted on the frame, provided that the mass (load) is well distributed in the application. Read more about the XL36 or contact us!

-

Das XL36-Gehäuse ist das längste und das dünnste Dynnox. Die Vorder- und Rückseite sind gleich breit. Das Auto-Interface ist nicht im Lieferumfang enthalten. Aufgrund seiner Länge und Breite wird er oft verwendet, wenn auch genügend Platz im Auto wichtig ist. Eine Anwendung von ca. 50 cm wide, 140 long and 120 high can be mounted on the frame, provided that the mass (load) is well distributed in the application. Lesen Sie mehr über die Dynnox XL36 or Kontaktieren Sie uns!

-

Der komplette XL36 besteht aus dem Chassis L46 + der Autoschnittstelle + der Holzplatte L46. Damit haben Sie alles, was Sie für den Dynnox XL36 benötigen. Das mobile Dynnox Transportsystem ist in drei Dimensionen erhältlich und kann in allen Arten von Firmenfahrzeugen eingesetzt werden. Der XL36 ist unser schmalstes Modell.

-

The chassis L46 is the shortest Dynnox. The car interface is not included. The front is 10cm shorter than the back due to the adjustment of the legs when the chassis is loaded. Due to its length in combination with its maneuverability, it is often used indoors. An application of approx. 60 cm width, 120 length and 120 hight can be mounted on the frame, providing that the mass (load) is well distributed in the application Read more about the L46 or contact us!

-

The vehicle interface is made of three core parts: the loading platform, the loading tray and the wooden plate. The Carrier L46 is not included. The vehicle interface has three essential functions: A) due to the loading tray it unlocks the mechanism. See art. loading tray B) it guides the chassis in the vehicle. C) it locks the chassis in the vehicle.

-

Die Fahrzeugschnittstelle besteht aus drei Kernteilen: der Ladeplattform, der Ladeschale und der Holzplatte. The Carrier L46 is not included. Die Fahrzeugschnittstelle hat drei wesentliche Funktionen: A) durch die Ladeschale wird der Mechanismus entriegelt. Siehe Art. Ladeschale B) es führt das Fahrgestell im Fahrzeug. C) Es verriegelt das Fahrgestell im Fahrzeug.

-

Das Fahrgestell L46 ist der kürzeste Dynnox. Das Auto-Interface ist nicht im Lieferumfang enthalten. Die Vorderseite ist 10 cm kürzer als die Rückseite, da die Beine beim Beladen des Fahrgestells verstellt werden. Aufgrund seiner Länge in Kombination mit seiner Manövrierfähigkeit wird er häufig in Innenräumen eingesetzt. Eine Anwendung von ca. 60 cm Breite, 120 Länge und 120 Höhe können auf dem Rahmen montiert werden, vorausgesetzt, dass die Masse (Last) in der Anwendung gut verteilt ist Lesen Sie mehr über die Dynnox L46 or Kontaktieren Sie uns!

-

The XL36 chassis is the longest and the thinnest Dynnox. The front and back are the same width. The car interface is not included. Due to its length and width, it is often used when enough space in the car is also important. An application of approx. 50 cm wide, 140 long and 120 high can be mounted on the frame, provided that the mass (load) is well distributed in the application. Read more about the XL36 or contact us!

-

Das komplette L46 besteht aus dem Chassis L46 + der Autoschnittstelle + der Holzplatte L46. Damit haben Sie alles, was Sie für den Dynnox L46 benötigen. Der Dynnox L46 bildet die Grundlage für jedes schmale mobile Transportsystem in Firmenfahrzeugen. Das Fahrgestell wiegt nur 80 kg und hat eine Tragfähigkeit von nicht weniger als 250 kg! Sie können eine unserer bewährten Anwendungen wählen oder ein Installationsmodul entwerfen, das perfekt zu Ihrer Situation passt; das intelligente System hält alles leicht und einfach beweglich.

-

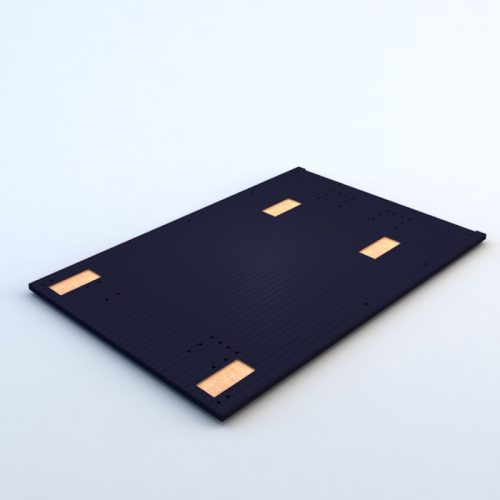

The positioning of all parts is pre-drilled and milled on both sides of the wooden plate. This makes mounting the parts of the vehicle interface on the car plate a kind of puzzle.

Application

This plate is for the vehicle interface XL53Option

When the option of pneumatic tires is chosen, the wooden plate becomes 7 cm wider but not longer.Dimensions

934 x 1470 x 15mmSafety

The positioning of the parts must be very accurate due to the positioning and locking of the chassis on the vehicle interface. -

The positioning of all parts is pre-drilled and milled on both sides of the wooden plate. This makes mounting the parts of the vehicle interface on the vehicle plate a kind of puzzle.

Application

This plate is for vehicle interface XL53Dimensions

864 x 1470 x 15mmSafety

The positioning of the parts must be totally accurate due to the positioning and locking of the chassis on the vehicle interface. -

The loading tray is the platform on which the frame comes first. The sloping side of the platform ensures that the frame is lifted from the ground. The loading wheel should be halfway along the slope of the loading tray. At the front of the loading tray is also a small “platform” with a hook on it. This activates the mechanism and unlocks the legs. It is therefore important that the chassis is never higher than the loading tray.

Application

Vehicle interface XL53 in combination with pneumatic tire option -

The loading tray is the platform on which the frame comes first. The sloping side of the platform ensures that the frame is lifted from the ground. The loading wheel should be halfway along the slope of the loading tray. At the front of the loading tray is also a small “platform” with a hook on it. This activates the mechanism and unlocks the legs. It is therefore important that the chassis is never higher than the loading tray.

Application

Vehicle interface XL53 Vehicle interface XL46 in combination with pneumatic tire option -

The safety activator is part of the chassis. The safety activator is the most important part of Dynnox. When loading an undercarriage in a vehicle, the unlocking of the legs is hereby ensured. But also the locking of the legs when unloading a chassis. This part is for the Dynnox XL53. Note: the performance of the legs must be reset when these parts are replaced. See manual.

Applications

Dynnox XL53 -

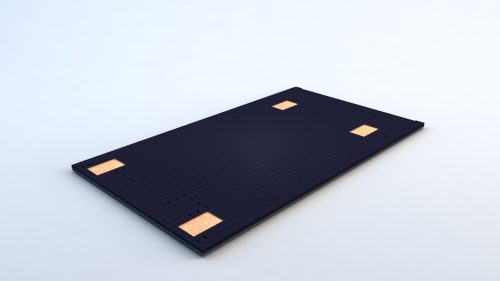

The positioning of all parts is pre-drilled and milled on both sides of the wooden plate. This makes mounting the parts of the vehicle interface on the car plate a kind of puzzle.

Application

This plate is for the vehicle interface XL36Option

When the option of pneumatic tires is chosen, the wooden plate becomes 7 cm wider but not longer.Dimensions

764 x 1470 x 15mmSafety

The positioning of the parts must be very accurate due to the positioning and locking of the chassis on the vehicle interface. -

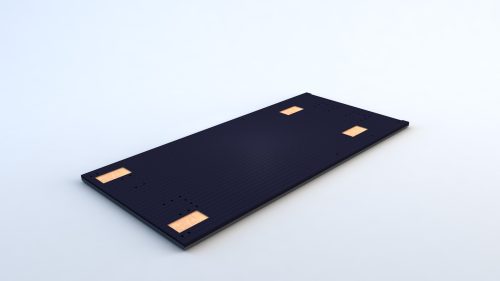

The positioning of all parts is pre-drilled and milled on both sides of the wooden plate. This makes mounting the parts of the vehicle interface on the vehicle plate a kind of puzzle.

Application

This plate is for vehicle interface X36.Dimensions

694 x 1470 x 15mmSafety

The positioning of the parts must be totally accurate due to the positioning and locking of the chassis on the vehicle interface. -

The vehicle interface is made of three core parts: the loading platform, the loading tray and the wooden plate. The Carrier XL36 is not included. The vehicle interface has three essential functions: A) due to the loading tray it unlocks the mechanism . See art. loading tray B) it guides the chassis in the vehicle. C) it locks the chassis in the vehicle.

Application:

Dynnox XL36 -

The loading tray is the platform on which the frame comes first. The sloping side of the platform ensures that the frame is lifted from the ground. The loading wheel should be halfway along the slope of the loading tray. At the front of the loading tray is also a small “platform” with a hook on it. This activates the mechanism and unlocks the legs. It is therefore important that the chassis is never higher than the loading tray.

Application

Vehicle interface XL36 in combination with pneumatic tire option -

The loading tray is the platform on which the frame comes first. The sloping side of the platform ensures that the frame is lifted from the ground. The loading wheel should be halfway along the slope of the loading tray. At the front of the loading tray is also a small “platform” with a hook on it. This activates the mechanism and unlocks the legs. It is therefore important that the chassis is never higher than the loading tray.

Application

Vehicle interface XL36 -

The Safety activator is part of the chassis. The Safety activator is the most important part of Dynnox. When loading an undercarriage in a vehicle, the unlocking of the legs is hereby ensured. But also the locking of the legs when unloading a chassis. This part is for the Dynnox XL36. Note: the performance of the legs must be reset when these parts are replaced. See manual.

Applications

Dynnox XL36 -

The complete XL36 is composed of the chassis L46 + the car interface + the wooden plate L46. With this you have everything you need for the Dynnox XL36. The mobile Dynnox transport system is available in three dimensions and can be used in all types of company vans. The XL36 is our narrowest model. The Dynnox XL36 forms the basis for every narrow mobile transport system in company vehicles. The undercarriage weighs only 80 kg and has a bearing capacity of no less than 250 kg! You can select one of our proven applications or design an installation module that perfectly matches your situation; the smart system keeps everything light and easily moveable. For this model a detachable auto interface is available. This allows flexible deployability of the Dynnox. This way you can use the Dynnox for project-based work, easily smooth out the load floor or take out the Dynnox in case of an exchange of company vehicles. Read more about the XL36 or contact us!

Dimensions

The Dynnox XL36 has a frame width of 360 mm. The detachable auto interface is structured around a wooden plate of at least 12 mm thickness. From 16 cm above the frame the installation module could be up to 20 cm wider. -

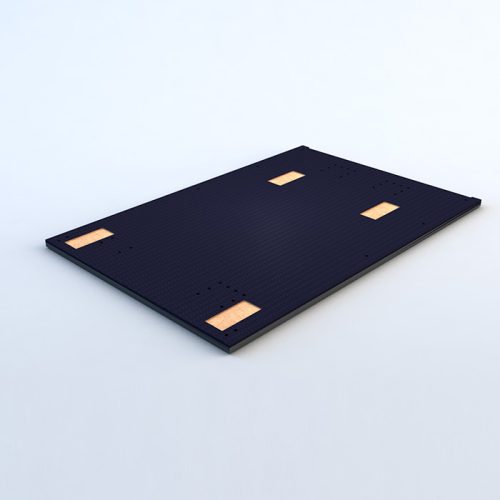

The positioning of all parts is pre-drilled and milled on both sides of the wooden plate. This makes mounting the parts of the vehicle interface on the car plate a kind of puzzle.

Application

This plate is for the vehicle interface L46.Option

When the option of pneumatic tires is chosen, the wooden plate becomes 7 cm wider but not longer.Dimensions

864 x 1185 x 15 mmSafety

The positioning of the parts must be very accurate due to the positioning and locking of the chassis on the vehicle interface. -

The positioning of all parts is pre-drilled and milled on both sides of the wooden plate. This makes mounting the parts of the vehicle interface on the vehicle plate a kind of puzzle.

Application

This plate is for vehicle interface L46.Dimensions

794 x 1185 x 15mmSafety

The positioning of the parts must be totally accurate due to the positioning and locking of the chassis on the vehicle interface.